7 "Secrets" of Small Water Pump Manufacturers

Estimated Reading Time: 12 minutes

There is a view that products made in China are of poor quality. But the truth is that many high-quality products are also made in China daily. There are many secrets in China manufacturing you should know when you plan to buy from China.

If you are a sourcing manager looking for high-quality small water pumps for your equipments, I will tell you 7 “secrets” that pump manufacturers might do in this article. I hope it can help you to avoid the manufacturers described below.

Secret 1: No investment in R&D

Most small water pump factories do not invest in R&D.

The direct reason is that China’s manufacturing industry is very competitive, and the profit margins of factories are too low to develop new technologies and products.

The deeper reason is IP violations. Although the Chinese government has been vigorously improving the intellectual property protection system, IP violations are still ubiquitous. Rather than developing new products & technology, many factories prefer to copycat.

However, a copycat is very deceptive in the water pump industry. They can only imitate the appearance but can not achieve the same performance, functions, and longevity.

How to identify whether the factory has an R&D team? Talk to their engineers, ask technical questions, find solutions instead of simply purchasing, and propose customized services.

Secret 2: Win at price and lack of after-sales service

Purchasing small water pumps definitely needs after-sales service.

When you develop a project, you need to repeatedly modify the parameters of the pump to perfectly fit your machine. When your customer encounters problems with your machine, you need a cooperative pump supplier to help solve the problem together.

To get orders, especially for big quantities, many factories will lower prices without limit. The result is that they have to cut the product quality a bit to save costs. And also, because of this, they hate and refuse after-service.

A few years ago, we met a new aquarium pump customer. They complained to us that the supplier they had worked with for many years ran away with their 200,000 euro deposit.

Before working with them, we helped investigate their old supplier, which turned bankrupt. The company had disappeared entirely in China.

Therefore, you should be cautious about products priced below common sense because only reasonable profits can guarantee good after-sales service.

Secret 3: Make an impossible Promise

In China, most factories hire people fluent in English as salespeople instead of professionals with products because it’s hard to find someone good at both English and products. So you may find a 200 staffs company’s salesman has no idea about their products.

When inquiries are received, they will often promise all your requests to stand out from the crowd without figuring it out, especially when you send group inquiries on the Alibaba platform.

Click to see why you should avoid purchasing directly on Alibaba.

Unfortunately, when you decided to start working with them, you found they did not have the capability they promised. Worse, when you have paid, you find the products received are not as promised.

The solution is asking for customized samples for testing before bulk purchasing.

Secret 4: Exaggerated false Parameters

Exaggerating false parameters is a common trick many small water pump factories use because many customers don’t know how to verify the authenticity of the parameters.

Generally speaking, the pump’s max head and flow rate will increase with its physical size. Therefore, we would think that the larger the size of the pump, the better the performance.

Based on this point of view, some pump factories produce large but poor-performance pumps. However, simply increasing the size is very easy and costs almost nothing.

They exaggerate the label’s head and flow rate information and win the market at a low price. You thought you were buying a better cost-effective pump when the manufacturer was just tricking you.

Following is a short video showing the comparison of our 5000LPH pump with other brands of 6000LPH and 7500LPH pumps.

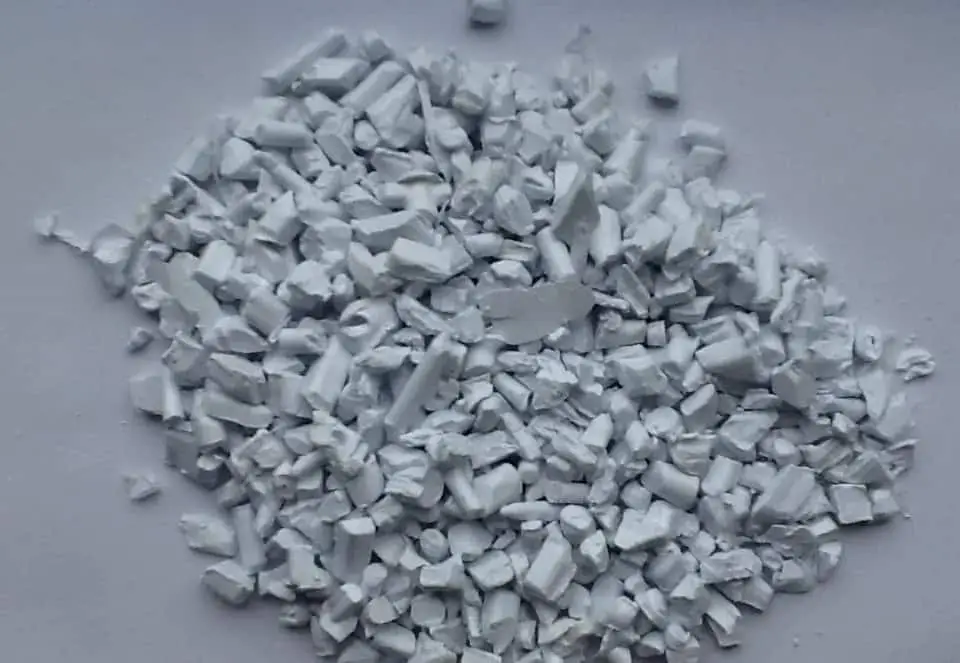

Secret 5: Use Poor quality raw materials: Plastic

Engineering plastics are used instead of metals for making pump bodies of small water pumps. The pump body is similar to the skeleton of the human body, and its primary function is to place every part in a proper position and to protect them to run normally. Therefore, many unique requirements exist, such as high rigidity, high strength, good dimensional stability, high-temperature resistance, corrosion resistance, etc.

The engineering plastics used in small water pump production are partly imported and domestically produced. Imported engineering plastics are expensive, possibly twice or more than domestic ones.

To reduce costs, most factories will choose domestic engineering plastics. But even worse, some factories use off-grade or regrind plastic.

Using off-grade plastic or excessive regrind plastic will lessen or compromise the mechanical properties of the small water pump, then reduces the reliability and causes it to fail prematurely. The main failure situations include cracking and deformation, etc.

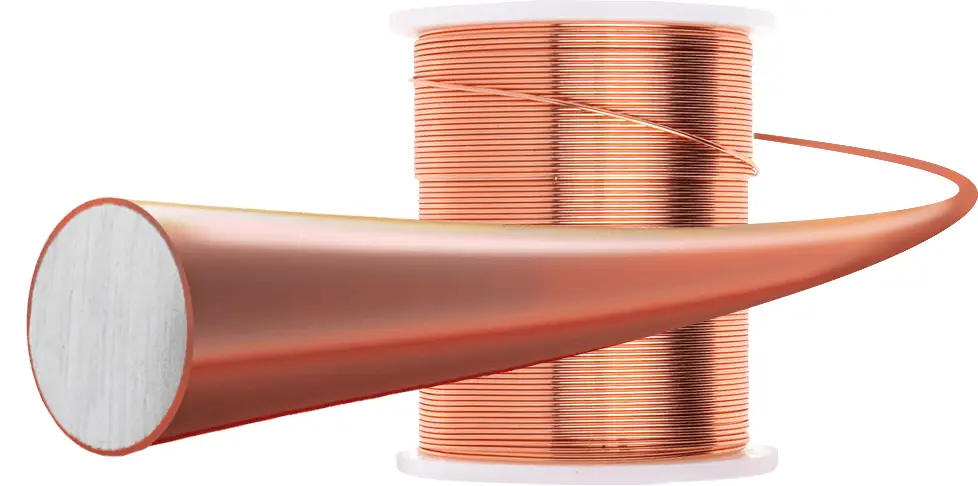

Secret 6: Use Poor quality raw materials: Copper Wire

Enameled wire (also known as winding wire) is another essential raw material in manufacturing small water pumps. It is used to create stator coils to convert electrical energy into mechanical energy. High-quality copper wire is a benefit for improving small water pumps’ energy efficiency and ensuring small water pumps’ reliability and service life.

The winding coil will generate lots of heat when the pump works. Due to the compact structure, the small water pump does not have as good a heat dissipation environment as the traditional water pump. So, on the one hand, we need to improve the heat dissipation of the small water pump, and on the other hand, we must use excellent enameled copper wire with a high-temperature class.

Some small water pump manufacturers will use copper-clad aluminum wires instead of pure copper wires to reduce costs. The primary function of copper-clad aluminum wires is to transmit signals, which cannot carry excessive current. The advantage of copper-clad aluminum wires is weight reduction and cost reduction, and the disadvantage is that the conductivity of aluminum is two-thirds of copper.

Using copper-clad aluminum will significantly reduce the long-term reliability of small water pumps.

Secret 7: Use Low-quality Chips

The MCU (Microcontroller Unit) is widely used in small water pump manufacturing. It is the command center of the water pump. We can add various functions to the pump to make it intelligent by writing programs. Click to view what functions we can add to a small water pump.

There are hundreds of MCU manufacturers in China, but the market share of domestic MCUs is only 5%. Why? Compared with the functional design of the chip, the reliability is more important to the downstream manufacturers.

The fault tolerance rate acceptable to the general consumer industry is about 3/10,000 to 5/10,000. Some particular industries require the fault tolerance rate to be infinitely close to 0. This is almost impossible for most small Chinese MCU manufacturers.

The business model of small MCU manufacturers is simple, copying, reducing profits, and winning at prices. As a result, the price of domestic MCUs may be only one-third or even one-tenth of imported genuine MCUs.

Using low-quality MCU chips can significantly reduce the cost of the small water pump, and there will be no problems in the short term. However, some occasions requiring the pump to run continuously for a long time may cause irreversible consequences, such as machine burning.

BLDC Pump Co., Ltd Introduction

BLDC PUMP Co., Ltd. has focused on small water pump R&D and production since 2009. Unlike our peers who chose to provide low-price, low-quality products to close more deals, we insist on making reliable products to win the market.

Our pump is, first and foremost, quality-based. It is primarily used in various types of equipment to protect the core component. It has high efficiency & high durability with a compact size and is very quiet.

Instead of only selling a product, we provide a professional pre-consultation and a flexible, customized solution to meet our customers’ requirements. We want to serve as a stepping stone and assist you in boosting your business.

If you’d like some more information, don’t hesitate to Get a Quote now by clicking the button below.