Difference between brushless and brushed

We’ve written a Brushless DC Pump Definitive Guide to cover this topic. Please visit it and get a comprehensive view of brushless DC pumps.

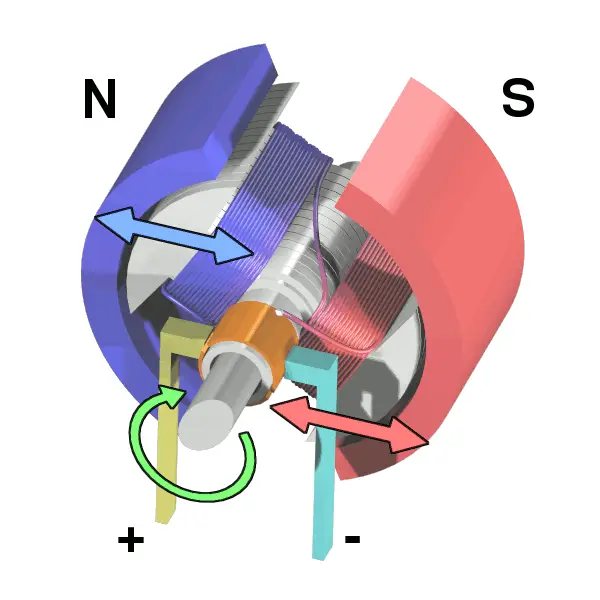

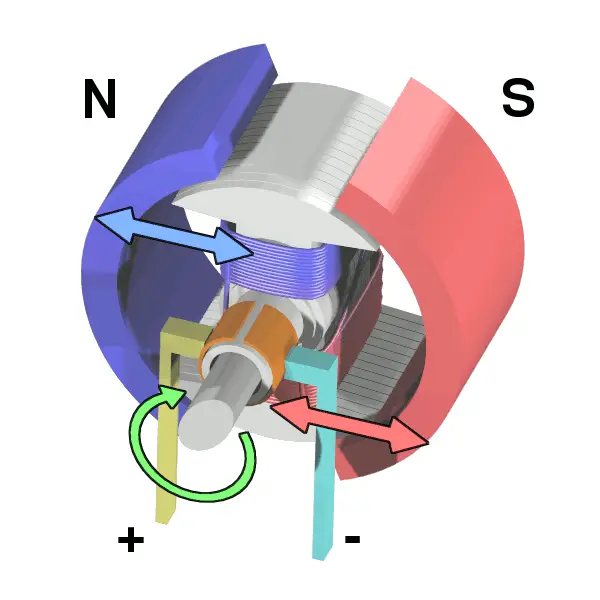

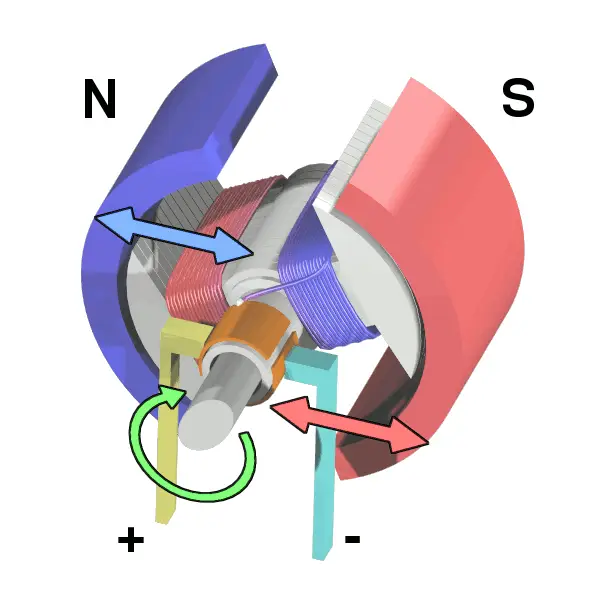

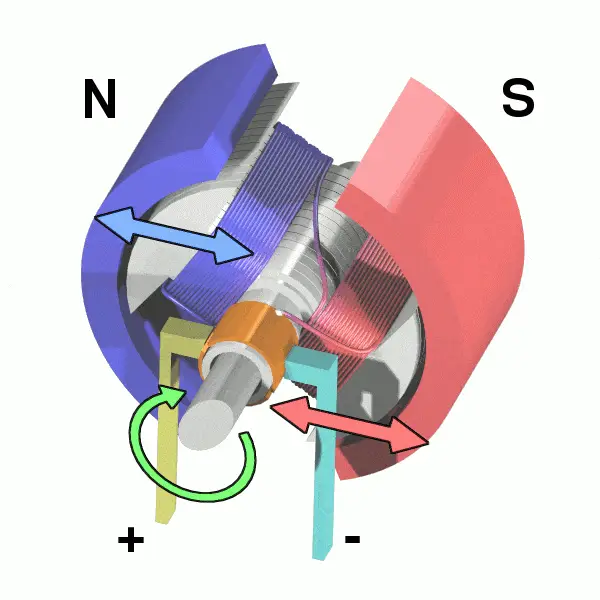

Brushed DC motor Rotation

Step 1. The armature is pushed away from the left magnet and drawn toward the right.

Step 2. The armature continues to rotate.

Step 3. When the armature becomes horizontal, the commutator reverses the direction of the current, reversing the magnetic field.

Step 4. The process then repeats.

Brushless DC motor

Electronic commutation replace of the mechanical commutator

Due to this innovation, some limitations of brushed motors were overcome by brushless motors. They include higher efficiency, no mechanical wear and no spark. These benefits come at the cost of more complex and more expensive control electronics.

Brushless motors offer several advantages over brushed DC motors, including high torque to weight ratio, more torque per watt (increased efficiency), increased reliability, reduced noise, longer lifetime (no brush and commutator erosion), elimination of ionizing sparks from the commutator, and overall reduction of electromagnetic interference (EMI).