Engineered for High-Density Compute: Precision BLDC Pumps for AI & Data Center Liquid Cooling

Eliminate thermal throttling with 30,000h+ lifespan, leak-proof magnetic drive, and precise PWM control. Trusted by OEMs for Direct-to-Chip and Immersion Cooling.

AI's Heat Density Is Skyrocketing.

Is Your Cooling Strategy Obsolete?

With rack densities surpassing 20kW, traditional air cooling leads to throttling and hardware failure.

Extreme Heat Loads

Concentrated heat from GPUs overwhelms air convection, risking component lifespan.

Density Limitations

Air cooling forces you to space out servers, wasting valuable data center floor space.

Risk of Downtime

Thermal throttling leads to system instability and catastrophic downtime for critical AI tasks.

Rising Energy Costs

Fans consuming >20% of total power. PUE > 1.5 is no longer sustainable.

Why Traditional Air Cooling Fails in the 500W+ TDP Era

Traditional Air Cooling

Noise Pollution

BLDC Liquid Cooling

< 35 dB (Silent)

Don’t let pump failure risk your million-dollar AI clusters.

From Concept to Mass Production: We Build What You Design

We bridge the gap between your design requirements and manufacturing reality. Our engineering team acts as an extension of yours—reviewing blueprints, optimizing structures, and ensuring the final pump fits your system perfectly.

Electrical Customization

- Custom Voltage (5V-24V) & Power

- PWM / 0-5V / VR Speed Control

- FG Signal (RPM) Feedback

Mechanical Integration

- Custom Inlet/Outlet Orientation

- Molex / JST / Waterproof Connectors

- Specific Cable Lengths

Material Engineering

- Ceramic Shafts for Long Lifespan

- Compatible with Glycol & Dielectrics

- Food Grade Materials Available

Accelerate Your Design Process

Need to check the fit? Request verified STP / IGES files for thermal simulation and chassis integration.

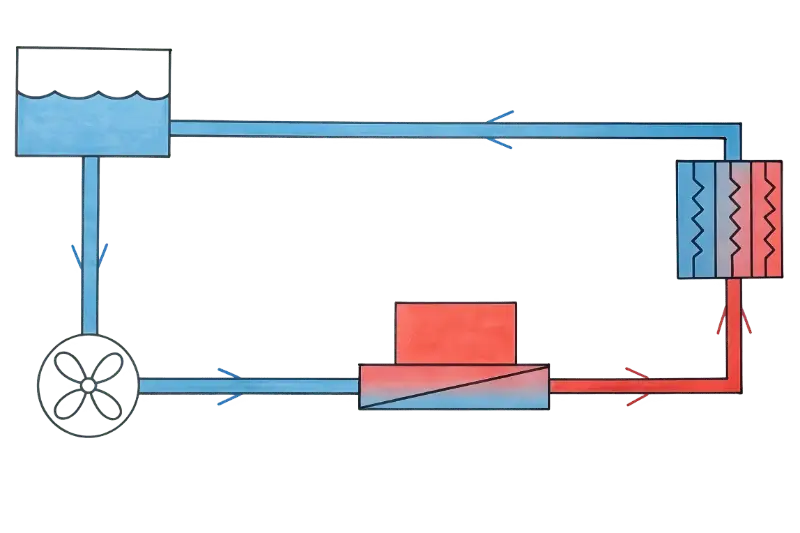

Optimized Fluid Dynamics for Closed-Loop Systems

With rack densities surpassing 20kW, traditional air cooling leads to throttling and hardware failure.

Pump - Features High Static Head (45M) to overcome micro-fin resistance. Zero-Leak Magnetic Drive ensures absolute reliability for AI clusters.

Water Tank - Buffers thermal expansion and removes air bubbles, ensuring a stable, maintenance-free hydraulic loop.

CPU/GPU - High-performance processors generating massive heat loads that require immediate, efficient thermal extraction.

Cold Plate - Dense micro-fins maximize surface area for heat transfer, efficiently absorbing heat from the chip above.

Radiator - Efficiently dissipates thermal loads into ambient air, returning cooled fluid to the reservoir to complete the cycle.

Overcoming Micro-Channel Resistance

Modern AI cold plates (CPU/GPU) use dense micro-fins that create high flow restriction. Our High Static Head (up to 45M) ensures sufficient flow rate even under high back-pressure.

Intelligent PWM Integration

Don't run at 100% all the time. The pump accepts PWM signals directly from the mainboard/BMS, dynamically adjusting speed based on real-time CPU thermal loads to save energy.

Zero-Leak Magnetic Drive

In a closed loop, seals are the weakest link. Our magnetic drive design eliminates the dynamic shaft seal, guaranteeing a leak-free operation for the server's entire lifecycle.

Meet our DC95 Series: Next-Generation Performance for AI Cooling

Specifically designed to meet the high flow and pressure requirements of demanding AI server cooling architectures. Building on our industry-leading pump technology, the DC95 offers unparalleled performance and reliability.

Motor

High-Efficiency Brushless DC

Design

Seal-less Magnetic Drive

Lifespan

Approx. 30,000 Hours

Noise

As low as ~35dB

Control

Integrated Electronics

DC95E

Max Flow: 6000L/H

Inlet: 3/4" thread

Outlet: 3/4" thread

DC95G

Max Flow: 20000L/H

Inlet: 1-1/4" thread

Outlet: 1-1/4" thread

Quality Assurance

Industrial-Grade Validation: Built to Outlast the Server

We don’t just design pumps; we torture-test them. Every DC95 unit undergoes a rigorous validation process to ensure zero failures in mission-critical environments.

Burn-in Test

Continuous operation at max load and high temperature to eliminate early-stage failures before shipping.

Noise Chamber

Validated in anechoic chambers to ensure noise levels strictly stay below 35dB at 1 meter distance.

Pressure Test

Static pressure testing of the pump housing to guarantee seal integrity under extreme hydraulic stress.

Climate Chamber

Cycling tests between extreme cold and heat to verify material stability and startup reliability.

ISO 9001:2015

CE Certified

RoHS Compliant

REACH Ready

Trusted by Innovators Worldwide

See how our engineering team helps global OEMs solve critical thermal challenges.

Perfectly matched our project needs.

We needed pumps for a new circulation system. BLDC offered customization services that perfectly matched our final project needs, and their team was always ready to assist with design.

350% sales increase in 2 years.

Delivery speed is super fast. With their custom labeling service and loyal partnership, my distribution business has seen a massive 350% increase in sales volume.

AI Server Cooling Pumps FAQs

Generally, the pumps can handle water, oil, and acid/alkaline solutions.

However, for specific or special liquids, testing and confirmation are required.

BLDC PUMP offers material adaptation services to ensure compatibility with the specific fluid the customer intends to use. Key materials used include ceramics and various carbon/graphite composites.

The pumps feature integrated electronic control units. Control programs can be customized, including features like PWM, 0-5V analog signal, etc.

Consultation with BLDC PUMP is advised for specific requirements.

We offer fast sample delivery for testing and evaluation, typically within 7 working days.

Our in-house manufacturing capabilities, including our own mold factory, winding facility, and injection molding plant, allow us to control production timelines and ensure timely delivery of orders. This also gives us greater flexibility for customization and allows us to respond quickly to your specific needs. Contact us to discuss your project timelines and volume requirements.

The pumps can be equipped with integrated protection functions, including dry-run protection.

This feature may be integrated based on customer requirements as part of the customization service. It’s important to specify if dry-run protection is needed for your application when discussing requirements with BLDC PUMP.

We offer a wide range of customization options to meet your specific needs. This includes voltage and wattage adjustments, flow rate and head pressure optimization, various plumbing connection choices, control integration capabilities, and branding and labeling options.

Ready to Optimize Your AI Cooling Performance and Reliability?

Don’t let inefficient cooling become the bottleneck in your AI infrastructure. Our engineers are ready to discuss your specific application and help you design a customized, reliable liquid cooling solution that ensures maximum uptime and performance.

- Free technical consultation with our engineering team

- Custom design recommendations based on your thermal requirements

- Detailed specifications and performance modeling

- Fast prototype delivery for proof-of-concept testing

Contact Our Engineers

We respect your privacy. Your information will only be used to respond to your inquiry and will never be shared with third parties.

Professional brushless DC pump manufacturer providing customized fluid solutions for global OEMs. Engineered for reliability, optimized for performance.

Engineering Tools

Featured Solutions

Contact Us

- Building B33, Tantou West Industrial Park, Baoan District, Shenzhen, China

- [email protected]